Machining collapsed areas with Constant Cut

When using the Constant Cut roughing strategy and clearing material from the outside, a situation can arise where the toolpath gets collapsed at the innermost areas. When running the toolpath on a machine, these areas can leave a thin wall of stock that can corrupt the part and even break the tool when moving close to these areas.

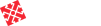

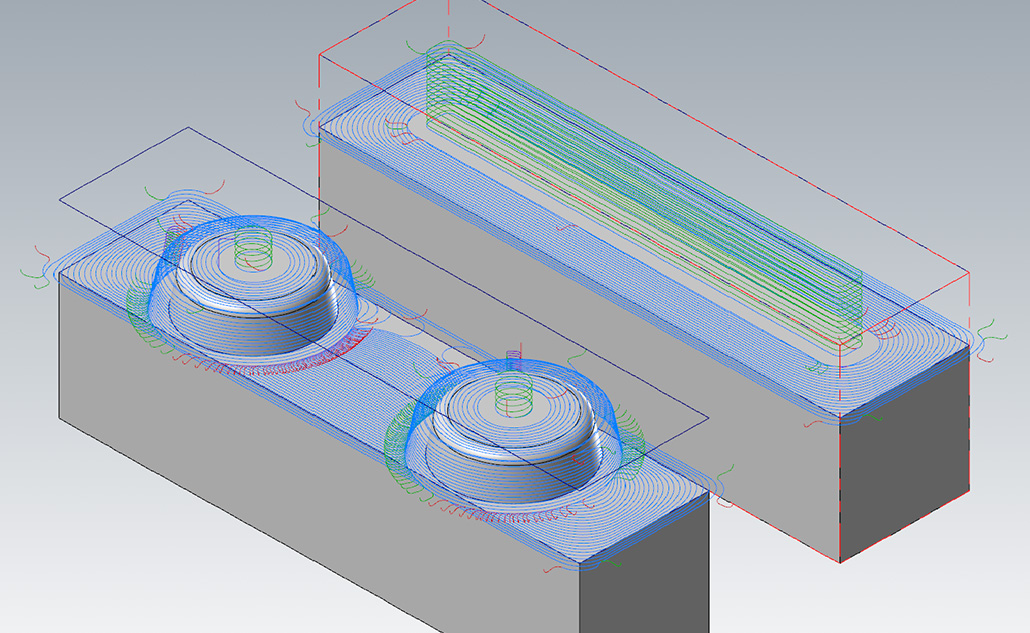

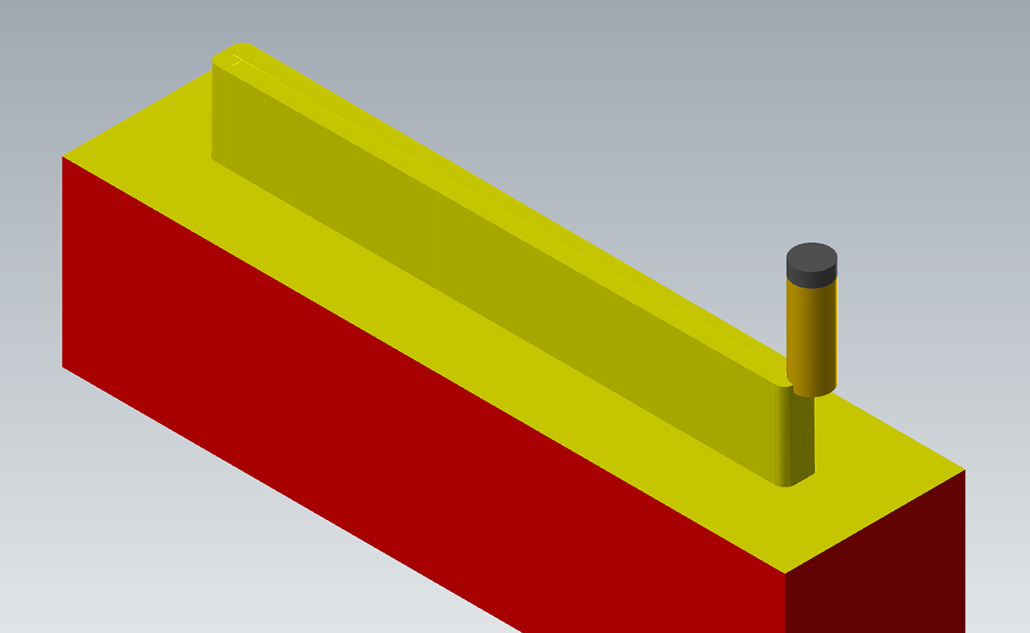

In the first image below, the collapsed areas are seen at the center of the rectangle and two circles. The second image shows the result of simulating the toolpath and clearly shows the wall remaining at the center of the rectangle.

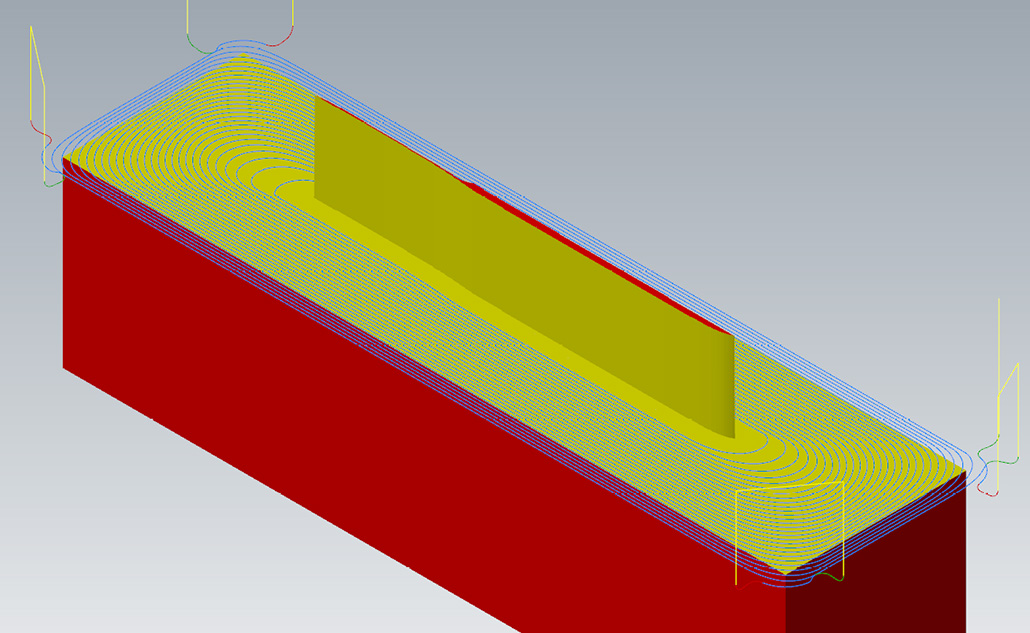

To accommodate such situations, HSM Performance Pack includes an option “Ramp islands” which enables more accurate machining of collapsed areas. The option applies a ramping toolpath to the collapsed area which ramps down from above the stock wall clearing it out. It also ensures that the stock wall is kept thick enough so that it does not break while ramping.

In the image below, the option “Ramp islands” is enabled under the Milling parameters tab.

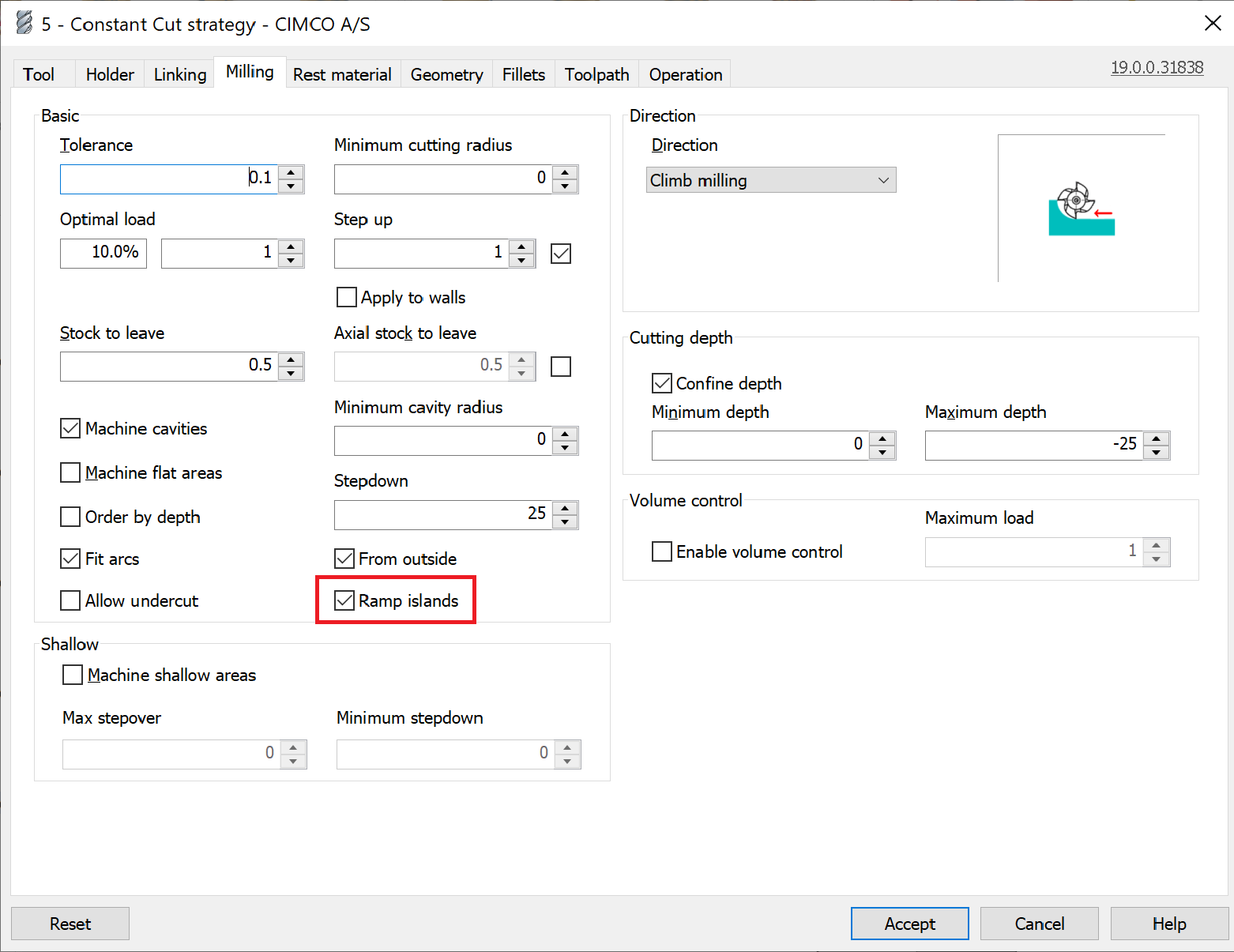

If more control is needed, ramp parameters such as Z-clearance, stepdown and angle can be configured in the Ramping section under the Linking tab.

With “Ramp islands” enabled and the ramping parameters configured, as shown in the image above, you get the following toolpaths.

When simulating the toolpath we can now see how a thicker stock wall is retained. This wall is then removed with the ramp starting at a Z-clearance above it and ramping down at a specified stepdown and ramp angle.

To try it out for yourself, download the example part “Constant Cut Islands Ramp Facing” which is also used in the images above.